Introduction

Next to the filter products for the steel circular tank, the use of pressure filtration, as the fiber ball filter. This product has a high filtering speed, large capacity, good effect, small footprint and so on. For a variety of biological wastewater treatment industry, direct filtration, wastewater reuse, in-depth pre-treatment, industrial water supply and swimming pool water circulation. SS in the water not more than 80mg / L SS can ensure that the effluent is less than 5mg / L.

Working principle

Fiber ball filter with its great surface area and porosity of suspended particles that touch the unifying role of tensile, adhesion of particles are suspended in water, the closure in the filter layer, because the filter was flexible, variable porosity in the filtration process , the filter bed cross-sectional and longitudinal uniformity of the porosity gradient to ensure a reasonable high-speed filtering and high-precision filters can be achieved simultaneously

Characteristic

Flexible media, can be compressed, easy to restore;

Ideal filter layer, on the loose, under dense;

Proportion of moderate and easy backwashing; can achieve high filtration rate, high-precision filter;

Of organic molecules, viruses, bacteria, colloids, iron and other impurities removal of a certain role;

Backwash water is low (about 1%), operating costs province;

Control can be manual control and automatic control in two ways,

|

Performance article |

Specific Index |

|

|

|

single processing |

15-210m3/h |

suspension strainaway rate |

85-96% |

|

rate of filtration |

30m/h |

Backwashing strength |

0.5m3/min.m2 |

|

design pressure |

0.6Mpa |

backwashing lasted |

20-30min |

|

drag coefficient |

series connection≤0.3Mpa |

cycle of backwash water quantity relative |

1-3% |

|

parallel connection≤0.15Mpa |

|

work cycle |

8-48h |

cut mud quantity of pollutants |

6-20kg/m2 |

|

coarse filter (single parallel) |

Influent SS ≤ 100mg / L, the effluent SS ≤ 10mg / L, 10 micron particle size removal efficiency ≥ 95% |

|

fine filter(single parallel) |

Influent SS ≤ 20mg / L, the effluent SS ≤ 2mg / L, 5micron particle size removal efficiency ≥ 96% |

|

Secondaray series connection |

Influent SS ≤ 100mg / L, the effluent SS ≤ 2mg / L, 5 micron particle size removal efficiency ≥ 96% |

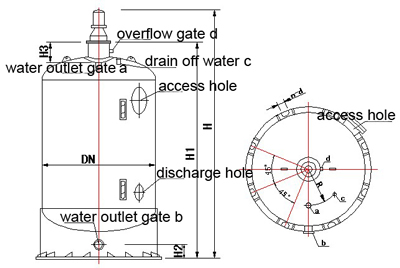

Single filter dimensions

Single filter technical paramter

|

|

Water treatment(T/H) |

power(KW) |

A Filter backwash water inlet |

B Filter backwash water inlet |

C exhaust |

D overflow |

|

YLGX-800 |

15 |

4 |

DN50 |

DN50 |

DN32 |

20 |

|

YLGX-1000 |

20 |

4 |

DN65 |

DN65 |

DN32 |

20 |

|

YLGX-1200 |

30 |

4 |

DN80 |

DN80 |

DN32 |

20 |

|

YLGX-1600 |

60 |

7.5 |

DN100 |

DN100 |

DN32 |

20 |

|

YLGX-2000 |

90 |

11 |

DN125 |

DN125 |

DN32 |

20 |

|

YLGX-2400 |

130 |

18.5 |

DN150 |

DN150 |

DN40 |

20 |

|

YLGX-2600 |

160 |

18.5 |

DN150 |

DN150 |

DN40 |

20 |

|

YLGX-2800 |

180 |

18.5 |

DN200 |

DN200 |

DN40 |

20 |

|

YLGX-3000 |

210 |

18.5 |

DN200 |

DN200 |

DN40 |

20 |

Single strainer shape dimension

|

|

DN |

H |

H1 |

H2 |

H3 |

Φ |

R |

n-d |

|

YLGX-800 |

800 |

3597 |

2866 |

250 |

420 |

1000 |

300 |

4-18 |

|

YLGX-1000 |

1000 |

3764 |

3000 |

220 |

450 |

1240 |

300 |

4-18 |

|

YLGX-1200 |

1200 |

4098 |

3280 |

220 |

480 |

1432 |

300 |

4-22 |

|

YLGX-1600 |

1600 |

4364 |

3480 |

200 |

480 |

1850 |

450 |

4-22 |

|

YLGX-2000 |

2000 |

4629 |

3645 |

210 |

450 |

2100 |

500 |

8-30 |

|

YLGX-2400 |

2400 |

5137 |

3970 |

210 |

500 |

2500 |

500 |

8-30 |

|

YLGX-2600 |

2600 |

5282 |

4070 |

200 |

520 |

2700 |

500 |

8-36 |

|

YLGX-2800 |

2800 |

5407 |

4170 |

200 |

530 |

2900 |

500 |

8-36 |

|

YLGX-3000 |

3000 |

5507 |

4270 |

200 |

550 |

3100 |

600 |

8-36 |

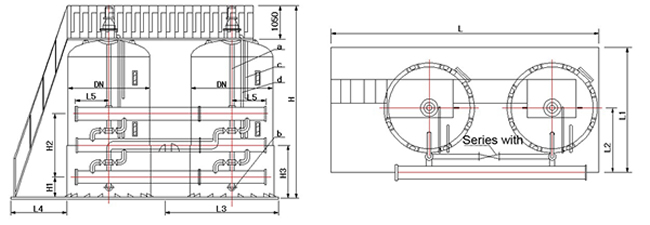

Series, parallel, automatic (manual) YLGX type shape structure next to the filter system

Series automatic (manual) YLGX type next to the filter system dimensions

|

DN |

L |

L1 |

L2 |

L3 |

L4 |

L5 |

H |

H1 |

H2 |

H3 |

W |

|

800 |

3100 |

1360 |

780 |

1200 |

700 |

533 |

3848 |

420 |

720 |

780 |

3280 |

|

1000 |

3390 |

1420 |

840 |

1320 |

750 |

603 |

3826 |

420 |

720 |

780 |

3420 |

|

1200 |

3800 |

1700 |

950 |

1500 |

800 |

711 |

4043 |

540 |

800 |

940 |

3890 |

|

1600 |

4600 |

2146 |

1190 |

1900 |

800 |

686 |

4294 |

505 |

1000 |

1005 |

4788 |

|

2000 |

5550 |

2525 |

1390 |

2300 |

950 |

782 |

4454 |

564 |

820 |

974 |

6075 |

|

2400 |

6400 |

2990 |

1650 |

2700 |

1000 |

852 |

4454 |

389 |

1100 |

939 |

6918 |

|

2600 |

6800 |

3230 |

1800 |

2900 |

1000 |

1088 |

4562 |

414 |

1000 |

914 |

7286 |

|

2800 |

7260 |

3540 |

2000 |

3100 |

1060 |

1098 |

4810 |

404 |

1200 |

1004 |

8010 |

|

3000 |

7660 |

3695 |

2050 |

3300 |

1060 |

1098 |

4830 |

403 |

1200 |

1003 |

8894 |

Parallel,automatic(manual)YLGX type shape structure next to the filter system

|

DN |

L |

L1 |

L2 |

L3 |

L4 |

L5 |

H |

H1 |

H2 |

H3 |

W |

|

800 |

3100 |

1360 |

780 |

1200 |

700 |

533 |

3848 |

420 |

720 |

780 |

3280 |

|

1000 |

3390 |

1420 |

840 |

1320 |

750 |

603 |

3826 |

420 |

720 |

780 |

3420 |

|

1200 |

3800 |

1700 |

950 |

1500 |

800 |

663 |

4043 |

540 |

800 |

940 |

3890 |

|

1600 |

4600 |

2146 |

1190 |

1900 |

800 |

759 |

4294 |

505 |

1000 |

1005 |

4788 |

|

2000 |

5550 |

2525 |

1390 |

2300 |

950 |

782 |

4454 |

564 |

820 |

974 |

6075 |

|

2400 |

6400 |

2990 |

1650 |

2700 |

1000 |

788 |

4454 |

389 |

1100 |

939 |

6918 |

|

2600 |

6800 |

3230 |

1800 |

2900 |

1000 |

1088 |

4562 |

414 |

1000 |

914 |

7286 |

|

2800 |

7260 |

3540 |

2000 |

3100 |

1060 |

1098 |

4810 |

404 |

1200 |

1004 |

8018 |

|

3000 |

7660 |

3695 |

2050 |

3300 |

1060 |

1098 |

4830 |

403 |

1200 |

1003 |

8894 |

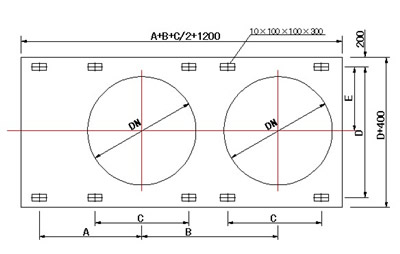

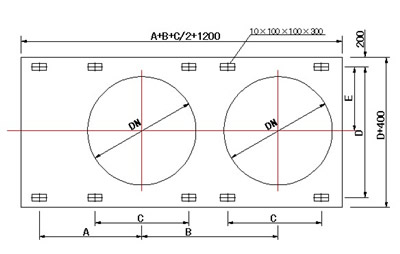

Series and parallel automatic (manual) YLGX type next to the filter basic size

|

DN |

A |

B |

C |

D |

E |

|

|

|

|

800 |

1230 |

1230 |

1200 |

600 |

1300 |

520 |

|

1000 |

1380 |

1380 |

1320 |

660 |

1360 |

520 |

|

1200 |

1420 |

1420 |

1500 |

900 |

1545 |

603 |

|

1600 |

1730 |

1730 |

1900 |

1300 |

1994 |

804 |

|

2000 |

2080 |

1900 |

2300 |

1700 |

2445 |

1065 |

|

2400 |

2350 |

2375 |

2700 |

1900 |

2910 |

1260 |

|

2600 |

2420 |

2460 |

2900 |

2300 |

3170 |

1370 |

|

2800 |

2580 |

2610 |

3100 |

2510 |

3460 |

1460 |

|

3000 |

2710 |

2750 |

3300 |

2700 |

3605 |

1555 |

|