Home >> Products

|

|

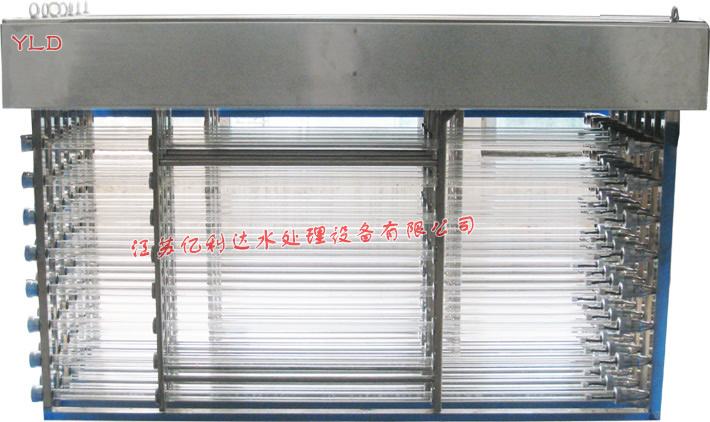

| Channel type ultraviolet disinfection equipment | |

UV disinfection is a principle of high-energy UV photon energy band of water damage to a variety of viruses, bacteria, pathogens, DNA and RNA structure, so that after the destruction of the loss of production capability and reproductive capacity of protein to achieve the purpose of sterilization. UV sterilization process is a physical process, the genetic material of microbial DNA or RNA has little direct effect of restrictive, the first known disease-causing micro-organisms can be in the 0.1-2 seconds to kill ultraviolet, visible, ultraviolet is one of the most broad-spectrum disinfection. And ultraviolet light will not add any substance to water, does not produce any by-products, high efficiency, environmental protection, safety features. The ultraviolet disinfection, there is no secondary pollution and by-products, water can be reused farmland, woodland and other irrigation or water back underground, to achieve resource. UV is divided into UVA, UVB and UVC tri-band, has a bactericidal function of the UVC, which the wavelength of 253.7nm UV strongest, general evaluation of the merits of the UV tube as long as the output depends on the performance of the band.  A.The ultraviolet UV system design and configuration of modules and designed to meet China's "urban water supply and drainage ultraviolet disinfection equipment" standard, to ensure that the provisions of this contract up to the water disinfection requirements

B. Degree of low pressure amalgam UV lamps in the high-end products - amalgam lamps (Amalgam UV Lamp). UV lamp output have the intensity of the UVC vendor testing and certification.

C.Issued by the UV lamp manufacturer to provide the technical parameters table lamp and lamp life provided by our guarantee

D.UV disinfection system to ensure that: the peak flow rate of 65% and UV light, the system can achieve at the end of lamp life effective UV dose, the dose of sterilizer biological test set is not less than 16,000 μws / cm ² (16mJ / cm ² )

E.UV disinfection system for the modular structure, placed in open drains. Placed outside the device is ready waterproof protection.

◆The modular structure of the low water resistance is less than the conventional module structure of the water resistance, small changes in water level before and after disinfection.

◆Water levels in line with IP68 rating standard for demanding applications

◆Cable part of the additional ring, effectively prevent the lamp cable short-circuit caused by water damage.High-quality corrosion-resistant stainless steel, tube and channel.

UV disinfection system is one of the core UV lamp, UV lamp as the company's world-class high-strength low-pressure UV lamps, installed in the module on the quartz tube, with flow direction parallel or perpendicular to the effective working life of the lamp of 9000-12000 hours, the single lamp up to 250-320W maximum power. Imported low-pressure high-temperature solid-state amalgam technology UV lamps to protect the life of 9000 hours.

Quartz sleeve installed in the module housing, the quartz tube UVC light transmittance greater than or equal to 85%, closed at one end to end, the other end of the open end, through the sub-seal design, protection class IP68, to effectively prevent water infiltration within the quartz tube to affect the normal operation of the UV lamp. High transmittance (UVT) of the quartz tube: high quality quartz tube to ensure good penetration of ultraviolet rays, to ensure maximum UV output intensity.

Electronic ballast is a core component of the system, highlight the advantages of UV disinfection system is the stability of electronic ballasts. Through the Germany introduction of the world's leading technology manufacturers, with high-pressure UV lamp instant start, high variable power output, and control of ballast netherlands Microelectronics Technology PLC Electronic ballasts installed in the ballast cabinet or module chassis. High-quality corrosion-resistant stainless steel, tube and signal cables sealed in sterilization module, not expose in the water and ultraviolet light. According to the customer dealing with water, water quality and disinfection requirements for different situations, to provide each module 3-20 a variety of design lamps.

Ballast cabinet: Cabinet protection rating of IP55, with air-conditioning cooling cabinet to prevent dust and damp outside air to enter, to ensure stable operation of electronic ballasts。

Electronic ballast module and inter-connected open channel junction box, junction box distribution by the central control cabinets delivery to each UV disinfection module.

Automatic centering control

Achieved through the man-machine interface control system and control of all parameters, such as on / off disinfection equipment, fault finding, the lamp running time, the working status of the UV light, parameter setting, etc., in order to facilitate the operator to monitor the operation of UV disinfection system for disinfection process to provide the most effective amount of fungicide。

2、 Automatic control center through the following methods and data exchange in the control room, to achieve remote control

◆Active or passive signal

◆Industrial Ethernet

◆PRSFBUS IP module

3、 UV disinfection equipment is according to user needs to choose the right brand and PLC interfaces. Standard configuration is for Siemens products

4、 Warning system

5、 Failure occurs, the alarm can sound, images, etc. to the user that what faults and fault location, fault can be found a few more records

Ultraviolet strength monitoring system

Each module has a set of UV intensity monitoring system, which includes UV sensor, UV intensity meter and other accessories, UV sensor installed to facilitate monitoring of underwater fouling of the quartz tube and UV light intensity.

Automatic cleaning system

The effect of UV disinfection are often subject to surface fouling of the quartz tube enormous influence, a significant decline in the UV intensity。

UV disinfection equipment comes with cleaning system. The cleaning technology can be set at any time, without affecting the equipment operation in the case of on-line self-cleaning surface casing, efficient and clean, low friction and no stuck phenomenon, for the UV disinfection system to provide a stable and efficient bactericidal effect。

Automatic cleaning system uses compressed air to drive, and UV intensity monitoring device linkage control, automatic cleaning, and convenient for manual / automatic switch working condition.

Water level control system

1、 Water level sensor

Water level sensor is a lamp for effective and necessary means of self-protection.UV germicidal lamp power is due to the high period, must be carried by the sewage of the period of natural cooling. Long exposed to the air when lit, the lamp burned is due to insufficient heat. We must ensure that the water level within the open channel to all the tubes immersed. However, UV light transmission in low water, when water level is too high, it will lead to disinfect the surface water layer is not satisfied. Therefore, the water level can not be too high within the open channel. Determination of open channel water level sensor line value, to ensure that drains the water level in the range of values to keep the design. When the open channel exceeds the set level for a long time minimum / maximum water level control system can automatically alert the lamp off.

1、 Pattern: Water level control weir gate

2、 Material: 304 stainless steel or construction completed

3、 Water way: Weir door with the top of the water, to ensure that the open channel to maintain a minimum water level and minimum water level changes. Within this range in all the North to keep the lamps submerged

4、 Advantage: High accuracy (changes in system flow rate of 1.3 hours, water level fluctuation range of less than ± 3cm), fast response, simple structure, easy installation, suitable for flow rate variation of the occasion, no complex mechanical transmission device, no external power and intervention the whole process of automatic adjustment.

5、 Head lost:less than 500mm

Installation: At the end of the outfall canals

|

|

|