Feature

1、Accurate filtering: You can choose different precision filter disk, there are 20μm, 50μm, 100μm, 130μm, 200μm variety of specifications based on water requirements.

2、Efficient backwash: fast and thorough backwashing, only about 20 seconds to complete.

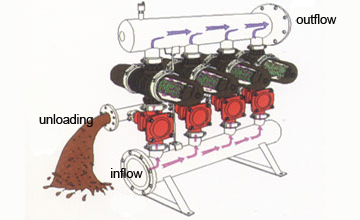

3、Fully automatic operation, continuous water: group comprising of filter backwash process alternating between work, backwashing, status, auto-switching ensures continuous water, the system pressure loss is small.

4、Standard: standard modular system design, the user can demand a choice, flexible, scalable, interchangeability.

5、Non-standard: flexible use of corner space, according to local conditions installation covers an area of very little.

6、Reliable operation and maintenance is simple: almost no routine maintenance, parts 100% factory testing and commissioning, without special tools, spare parts.

7、Long life: the high-tech plastic filter element is solid, no wear, no corrosion, practical verification of years of industrial filtration and backwash effects with the use of time variation.

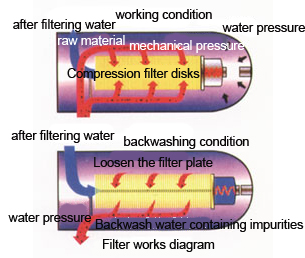

Working condition

Filter disc under the spring force and hydraulic action are tightly pressed together. But the passage of the water containing impurities, the impurity particles trapped.

Backwashing condition

The controller controls the valve to change the direction of flow. The disc is released, the spray nozzle located in the central disk along a tangent, so that the disc rotation, the solids retention plate is washed out.

Technical parameter

※Working pressure:0.25~0.8Mpa

※backwashing pressure:0.15~0.6Mpa

※backwashing time:5~20s can be adjusted

※wash water consumption:30~100L(Single filter head)

※System pressure loss:0.001~0.08Mpa

※Working temperature:4~75℃

PH:4.0~13

Design and choice

Each filter unit (4 ", 3" or 2 ") for the different quality of raw water and effluent accuracy requirements, water production is generally the raw water quality is divided into four categories:

A、Excellent water quality: city water, well water extracted from stable aquifers

B、General water quality: the circulation of cooling water, treated by precipitation, surface water after effective sedimentation and completely filtered

C、Poor water quality: poor quality of water from the aquifer extraction of groundwater, after the effective precipitation, but without or with little biological treatment, drainage, microbial blooms of surface water

D、Surface water, poor water quality: well water drawn from wells of dirty or rich ferromanganese, affected by the floods and without precipitation and without precipitation and biological treatment of drainage. D type water quality pretreatment improve a grade in order to ensure a good filtration system working state.

Equipment material

JY filter head by an enhanced polyamide plastic molding manufacturing, corrosion and wear, and can work under pressure 0.8Mpa.Filter disc material polypropylene plastic, collect and seal EPDM, out of the water and drain line for stainless steel.

Filtration grade reference

| Quality water pretreatment |

20 um |

| Drinking water pretreatment process with a small, thin tube nozzle protection |

50 um |

|

Circulating water filter ultrafiltration equipment protection |

100 um |

| Loop water filtration, pre-filter to the water treatment |

130 um |

| Reclaimed water r treatment, wastewater treatment |

200 um |

Disc filter selection parameter table (click to enlarge)

|

raw water quality |

good water quality |

General water quality |

overall dimensions |

weight |

|

filter grade |

200um |

130um |

100um |

50um |

20um |

200um |

130um |

100um |

50um |

20um |

L×W×H×Inlet&outlet water pipe diameter |

KG |

|

part number |

flow(m3/h) |

flow(m3/h) |

|

|

|

JY2-3 |

75 |

66 |

60 |

42 |

21 |

57 |

50 |

45 |

33 |

15 |

|

59 |

|

JY2-4 |

100 |

88 |

80 |

56 |

28 |

76 |

66 |

60 |

44 |

20 |

|

77 |

|

JY2-5 |

125 |

110 |

100 |

60 |

35 |

95 |

83 |

75 |

55 |

25 |

1855×719×1298×D150 |

95 |

|

JY3-3 |

|

≤100 |

≤90 |

≤60 |

≤30 |

≤84 |

≤73 |

≤66 |

≤48 |

≤22 |

815×865×1360×D200/D150 |

145 |

|

JY3-4 |

148 |

132 |

120 |

80 |

40 |

112 |

97 |

88 |

64 |

30 |

1115×865×1360×D200/D150 |

192 |

|

JY3-5 |

185 |

165 |

150 |

100 |

50 |

140 |

121 |

110 |

80 |

37 |

1415×865×1360×D200/D150 |

239 |

|

JY3-6 |

222 |

198 |

180 |

120 |

60 |

168 |

145 |

132 |

96 |

45 |

1715×865×1360×D200 |

286 |

|

JY3-7 |

259 |

231 |

210 |

140 |

70 |

196 |

169 |

154 |

112 |

52 |

2015×865×1360×D200 |

333 |

|

JY3-8 |

296 |

264 |

240 |

160 |

80 |

224 |

194 |

176 |

128 |

60 |

2315×865×1360×D200 |

380 |

|

JY3-9 |

333 |

297 |

270 |

180 |

90 |

252 |

218 |

198 |

144 |

67 |

2615×865×1360×D200 |

427 |

|

JY3-10 |

370 |

330 |

300 |

200 |

100 |

280 |

231 |

210 |

160 |

75 |

2915×865×1360×D200 |

474 |

|

JY4-3 |

296 |

264 |

240 |

160 |

80 |

224 |

194 |

176 |

128 |

60 |

2000×600×2400×D200 |

260 |

|

JY4-4 |

370 |

330 |

300 |

200 |

100 |

280 |

231 |

210 |

160 |

75 |

2600×600×2400×D200 |

350 |

|

JY4-5 |

494 |

441 |

401 |

267 |

134 |

374 |

323 |

294 |

214 |

100 |

3200×600×2400×D250 |

150 |

|

JY4-6 |

592 |

528 |

480 |

320 |

160 |

448 |

387 |

352 |

256 |

120 |

3800×600×2400×D250 |

550 |

|

|

Poor water quality |

Poorer water quality |

overall dimensions |

|

|

|

200um |

130um |

100um |

50um |

20um |

200um |

130um |

100um |

50um |

20um |

L×W×H×Inlet&outlet water pipe diameter |

KG |

|

|

|

|

|

|

|

JY2-3 |

40 |

33 |

30 |

22 |

10 |

24 |

21 |

19 |

13 |

7 |

1255×719×1298×D100 |

59 |

|

JY2-4 |

54 |

44 |

40 |

30 |

14 |

32 |

29 |

26 |

18 |

10 |

1255×719×1298×D100 |

77 |

|

JY2-5 |

67 |

55 |

50 |

37 |

17 |

40 |

35 |

32 |

22 |

12 |

1855×719×1298×D150 |

95 |

|

JY3-3 |

≤60 |

≤50 |

≤45 |

≤33 |

≤15 |

≤36 |

≤31 |

≤28 |

≤19 |

≤10 |

815×865×1360×D200/D150 |

145 |

|

JY3-4 |

80 |

66 |

60 |

44 |

20 |

48 |

41 |

37 |

26 |

14 |

1115×865×1360×D200/D150 |

192 |

|

JY3-5 |

100 |

83 |

75 |

55 |

25 |

60 |

52 |

47 |

32 |

17 |

1415×865×1360×D200/D150 |

239 |

|

JY3-6 |

120 |

99 |

90 |

66 |

30 |

75 |

62 |

56 |

39 |

21 |

1715×865×1360×D200 |

286 |

|

JY3-7 |

140 |

116 |

105 |

77 |

35 |

84 |

73 |

66 |

45 |

24 |

2015×865×1360×D200 |

333 |

|

JY3-8 |

160 |

132 |

120 |

88 |

40 |

96 |

83 |

75 |

52 |

28 , ,

|

2315×865×1360×D200 |

380 |

|

JY3-9 |

180 |

149 |

135 |

99 |

45 |

108 |

94 |

85 |

58 |

31 |

2615×865×1360×D200 |

427 |

|

JY3-10 |

200 |

165 |

150 |

110 |

50 |

120 |

103 |

94 |

65 |

35 |

2915×865×1360×D200 |

474 |

|

JY4-3 |

160 |

132 |

120 |

88 |

40 |

96 |

83 |

75 |

52 |

28 |

2000×600×2400×D200 |

260 |

|

JY4-4 |

200 |

165 |

150 |

110 |

50 |

120 |

103 |

94 |

65 |

35 |

2600×600×2400×D200 |

350 |

|

JY4-5 |

267 |

220 |

200 |

147 |

67 |

160 |

138 |

125 |

87 |

47 |

3200×600×2400×D250 |

150 |

|

JY4-6 |

320 |

264 |

240 |

176 |

80 |

192 |

165 |

150 |

104 |

56 |

3800×600×2400×D250 |

550 |

|