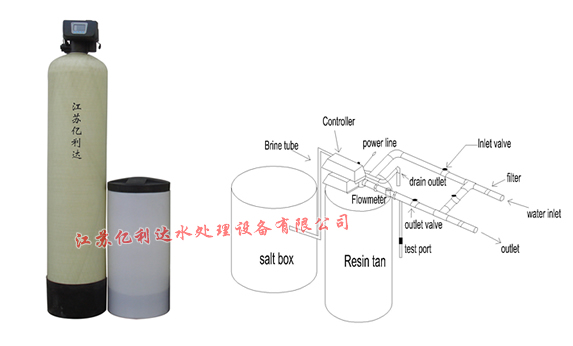

◆YLD system soft water

YLD company in China ten years ago since the first introduction of automatic water softener has been focused on the development and promotion of water softening equipment in line with China's national conditions. By the JK type, JM type, FLECK-and JB-type softener composed of YLD Series water softener, and the gathering, director of the public at home and abroad, for the different applications their users with the most reasonable and practical series of soft water equipment.

◆ lectotype prompt

| YLD system soft water |

Control model |

flow scope(t/h) |

particular characteristic |

Application Objects |

| JB type |

semi-automatic control value |

0.3-2.0 |

Manual start, automatic regeneration, no power |

Small civilian and commercial systems, automation ask for much, the pursuit of small systems economical |

| JK type |

full-automatic multitandem valve |

0.3-20 |

Hydraulic drive, no power |

Less than 20t / h of small systems, automatic running, unattended, simple control |

| FLECK type |

full-automatic control value |

0.5-50 |

Fully automatic operation, configuration flexibility |

Less than 50t / h softening system, fully automatic operation, simple control |

| JM type |

Controllers have conducted several valves |

8-400 |

Adjustable range, high accuracy |

In large industrial soft water system, operating conditions requires a more complex system |

◆ Single tank Specification

|

Part number |

Recommend produce a water yield(M3/H) |

tank size

D ×H(mm) |

salt box(L) |

resin amount(KG) |

resin amount(mm) |

|

YL-I-0.5 |

0.5 |

200×900 |

25 |

20 |

DN20 |

|

YL-I-1 |

1 |

250×1400 |

60 |

25 |

DN20 |

|

YL-I-2 |

2 |

300×1400 |

100 |

50 |

DN20 |

|

YL-I-3 |

3 |

350×1650 |

100 |

75 |

DN25 |

|

YL-I-4 |

4 |

400×1650 |

200 |

120 |

DN25 |

|

YL-I-5 |

5 |

500×1750 |

300 |

200 |

DN40 |

|

YL-I-6 |

6 |

600×1850 |

350 |

240 |

DN40 |

|

YL-I-10 |

10 |

750×1850 |

500 |

380 |

DN40 |

|

YL-I-15 |

15 |

900×1900 |

800 |

520 |

DN50 |

|

YL-I-18 |

18 |

900×2200 |

800 |

600 |

DN50 |

|

YL-I-25 |

25 |

1000×2200 |

1000 |

720 |

DN50 |

|

YL-I-30 |

30 |

1200×2400 |

1500 |

1000 |

DN80 |

|

YL-I-50 |

50 |

1500×2500 |

2000 |

1600 |

DN80 |

|

|

Recommend produce a water yield(M3/H) |

|

salt box(L) |

resin amount(KG) |

resin amount(mm) |

|

YL-II-2 |

2 |

300×1400 |

100 |

100 |

DN20 |

|

YL-II-3 |

3 |

350×1650 |

100 |

150 |

DN25 |

|

YL-II-4 |

4 |

400×1650 |

200 |

240 |

DN25 |

|

YL-II-5 |

5 |

500×1750 |

300 |

400 |

DN40 |

|

YL-II-6 |

6 |

600×1850 |

350 |

480 |

DN40 |

|

YL-II-10 |

10 |

750×1850 |

500 |

760 |

DN40 |

|

YL-II-15 |

15 |

900×1850 |

800 |

1040 |

DN50 |

|

YL-II-18 |

18 |

900×2200 |

800 |

1200 |

DN50 |

|

YL-II-25 |

25 |

1000×2200 |

1000 |

1440 |

DN50 |

|

YL-II-30 |

30 |

1200×2400 |

1500 |

2000 |

DN80 |

|

YL-II-50 |

50 |

1500×2500 |

2000 |

3200 |

DN80 |

Dual tank to run installation (for reference)