Operating Principle

Water hardness is mainly calcium (Ca2 +), magnesium (Mg2 +) ions formed. When the raw water containing hardness ions within the resin layer through the softener, the water of the calcium (Ca2 +), magnesium (Mg2 +) ion exchange resin adsorption was also the quality of the release of other objects of sodium (Na2 +) ions. Outflow from the water softener in the water is softened to remove hardness ions.

When the resin to absorb a certain amount of calcium (Ca2 +), magnesium (Mg2 +) ions, you must be regenerated. Regeneration of salt is salt water rinse tank in the resin layer, the hardness ions on the resin and then replace it, with the regeneration of waste water discharge tank, the resin to soften and restore the exchange capacity.

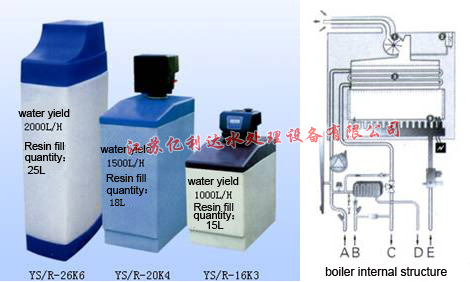

Multi-valve automatic water softener system consists of multiple control diaphragm (hydraulic and pneumatic), multi-valve controller, the resin tank, salt containers. Control procedures were based on pre-set diaphragm to control the various hydraulic issued a directive to complete the breaking of each pathway to achieve the regeneration of all running processes.

Scope of Application

Widely used in various industrial and commercial demineralized water preparation, such as boiler feed water, recycled water to add water, add water, heating and air conditioning systems and various industrial process water. Processing hundreds of tons of water to thousands of tons.

Main function&Feature

1、Full automatic motion

■ Built-time controller round the clock time control, the number of days at set intervals and regeneration time (default time is usually early morning) for renewable.

■ Control system according to the actual user condition and actual use of the raw water quantity calculation and design the most cost-effective soft water treatment program.

■ Circular function program

Run (IN SERV): the raw water at a certain pressure and flow rate through the softener, the ion exchange resin contained in the active groups in the Na + unit with water, Ca2 +, Mg2 + and other cation exchange, so that the water Ca2 +, Mg2 + plasma concentration decreased, so that the water has been softened.

Backwash (Backwash): saturated ion exchange resins, anti-renewable before the first wash, rinse to remove one of its purpose and end poly resin surface retention of suspended impurities and some of the broken resin, second resin layer of loose compaction, help with the regeneration of the resin particles in the regeneration of liquid contact, for the regeneration of ion exchange resins provide good conditions.

Brine regeneration (Brine): a certain salt concentration and flow of the fluid flow through the ion exchange resin layer, the saturation of the resin regeneration, to restore the original soft switching capability.

Flushing (Rinse): Clear resin layer residual salt solution, water washing to pass; pressed resin layer in order to achieve the best softening effect.

Salt tank water (Fill): dissolve the salt box to add the water softener regeneration salt, resulting in saturated salt solution used for the next regeneration.

2、Produce a uniform concentration of saturated salt solution

■Box of salt water from the bottom to add, settling down on the salt water from the salt water by natural convection mixing, until it reaches saturation.

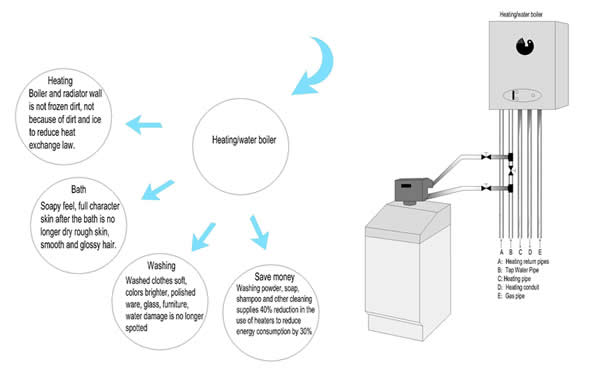

Wall hung gas heating water boiler(special water dispenser)

|